1. What Does an Optical Shutter Do?

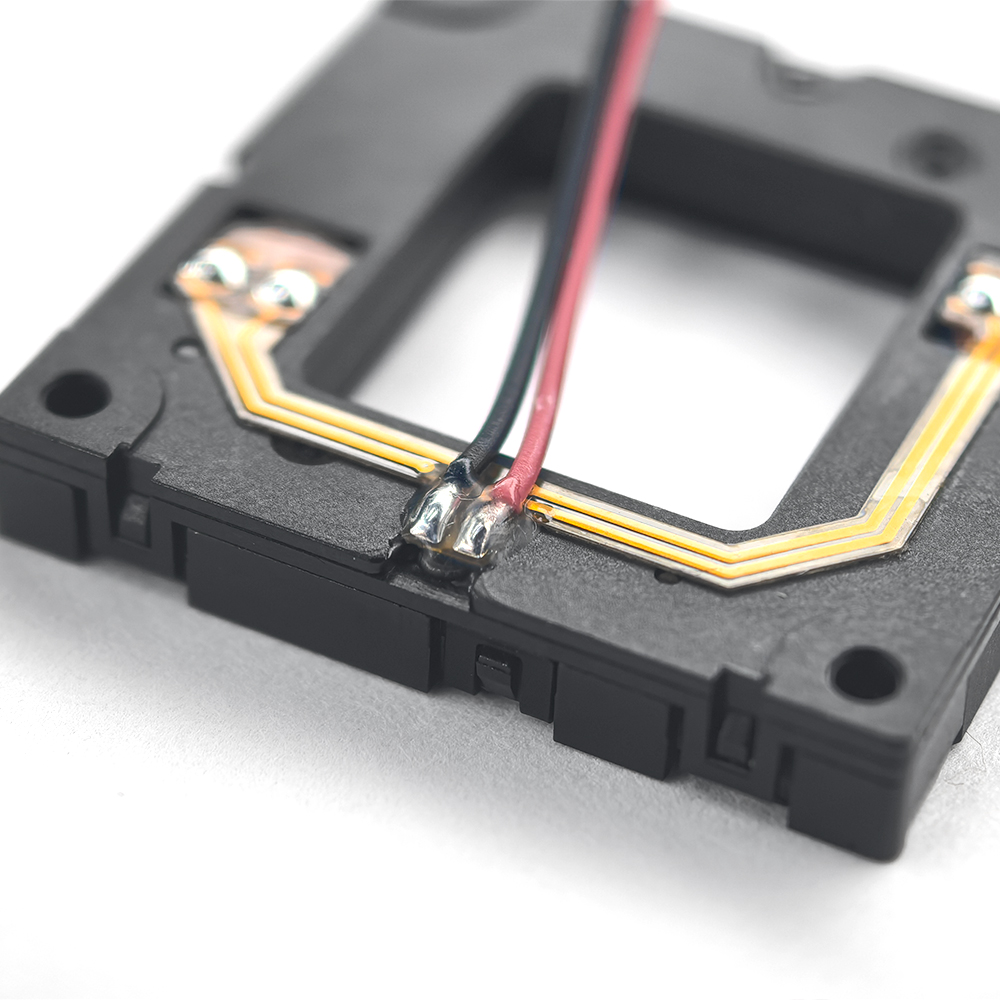

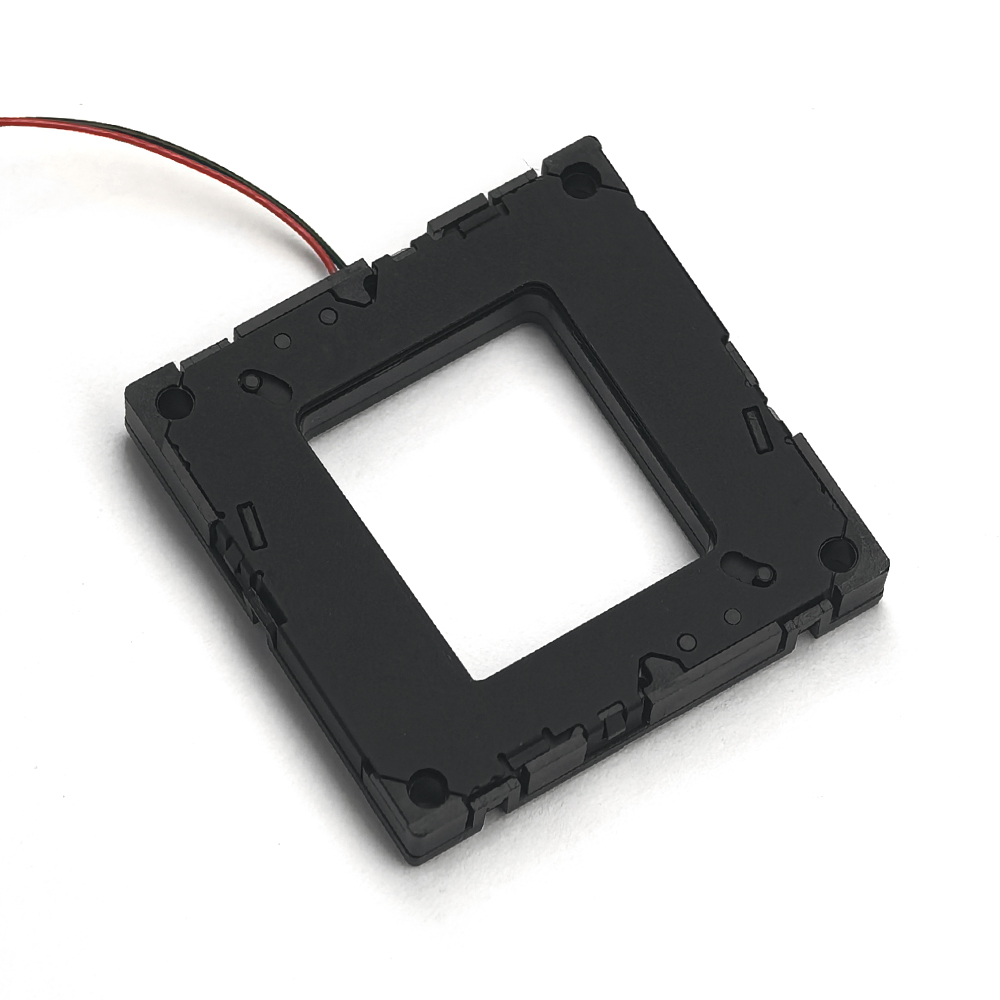

In a thermal imaging camera, the optical shutter is installed between the lens and the detector. It must be manually activated by setting a time interval in the camera’s menu. At each interval:

-

Blocking the Detector: The shutter closes for a brief moment, fully occluding the detector.

-

Resetting Parameters: This occlusion forces the detector’s internal reference frame to reset, compensating for any drift caused by changes in external temperature or humidity.

-

Temperature & Image Calibration: By periodically hiding the scene, the system corrects baseline errors and restores both accurate temperature readings and uniform image quality.

This process, commonly called Non-Uniformity Correction (NUC), is essential for low-end or mid-range detectors that cannot adapt on their own to environmental fluctuations.

The Role of the Shutter: Infrared Shutter Customization and Optical Shutter Solutions

2. Shutter vs. Shutter-Less: Key Differences

Shutter-Based Cameras

-

Frame Freeze: Every time the optical shutter opens and closes, image capture pauses. Viewers will notice the screen “stick” or “freeze” for one or two frames.

-

Lost Data: No thermal data is collected during the shutter movement, so there’s a brief gap in the footage.

-

Manual Interval: You choose how often the shutter cycles (e.g., every 30 seconds, every minute).

Shutter-Less Cameras

-

Adaptive Algorithm: Advanced software analyzes incoming data in real time and continuously corrects for drift—no physical shutter needed.

-

Uninterrupted Viewing: There is no frame loss or image freeze, delivering perfectly smooth thermal video.

-

Higher Intelligence: The detector and DSP/AI algorithms automatically optimize for ambient temperature and humidity changes.

3. Practical Applications & Cost Considerations

-

Shutter-Based Systems

-

Price Point: Significantly more affordable—popular in security, industrial inspection, and consumer electronics.

-

Manufacturing Simplicity: Simpler production and higher yield rates keep lead times short.

-

Use Cases: CCTV monitoring, building inspection, UAV/drone thermal surveys, where occasional frame freeze is acceptable.

-

-

Shutter-Less Systems

-

Price Premium: Costs are much higher due to premium detectors and sophisticated software licensing.

-

Complex Production: Longer validation cycles and lower throughput.

-

Use Cases: High-end R&D, extreme-environment monitoring, real-time dynamic imaging where zero interruption is mandatory.

-

4. Purchase Recommendations

-

Cost & Scale: For large deployments and budget control—where occasional image freeze is acceptable—choose a shutter-based thermal imaging camera.

-

Seamless Monitoring: If you require zero frame loss and continuous calibration, invest in a shutter-less system (budget accordingly).

5. Frequently Asked Questions (FAQ)

Q1: How often should I perform Non-Uniformity Correction (NUC) on a shutter-based camera?

A: The optimal interval varies by environment. In stable indoor settings, running NUC every 30–60 seconds is usually sufficient. In rapidly changing conditions (e.g., outdoor at dawn), shorten the interval to 10–20 seconds to maintain accuracy.

Q2: Can I adjust the shutter interval dynamically during a drone flight?

A: Most industrial thermal cameras allow interval settings via the onboard menu or remote commands. However, changing intervals “on-the-fly” may introduce additional frame freezes. Plan your settings before takeoff and adjust mid-flight only if necessary.

Q3: Does the brief frame freeze during shutter operation impact temperature accuracy?

A: No—the purpose of the shutter occlusion is to improve temperature accuracy by resetting the detector’s baseline. While you lose one or two frames, subsequent images are corrected for drift, resulting in more reliable measurements.

Q4: What are the power and performance trade-offs of shutter-less systems?

A: Shutter-less cameras need more processing power and often draw higher current to run real-time DSP or AI algorithms. Ensure your power supply can handle an extra 10–20% load compared to shutter-based models.

Q5: Is it possible to upgrade a shutter-based thermal camera to a shutter-less design?

A: Generally not—shutter-less systems require specialized detectors and embedded algorithms designed from the ground up. Retrofitting would involve replacing both the sensor module and processing firmware, which is usually not cost-effective.