Thermal imaging technology has become an essential tool across industries, from security and surveillance to industrial inspection, drones, and night vision systems. At the heart of this technology lies the thermal imaging core, a device that converts invisible infrared radiation into clear, visible thermal images. Within this system, one key element determines image quality and accuracy: the shutter.

Shutter vs. Shutter-less Cores

Thermal imaging cores are available in both shutter and shutter-less designs.

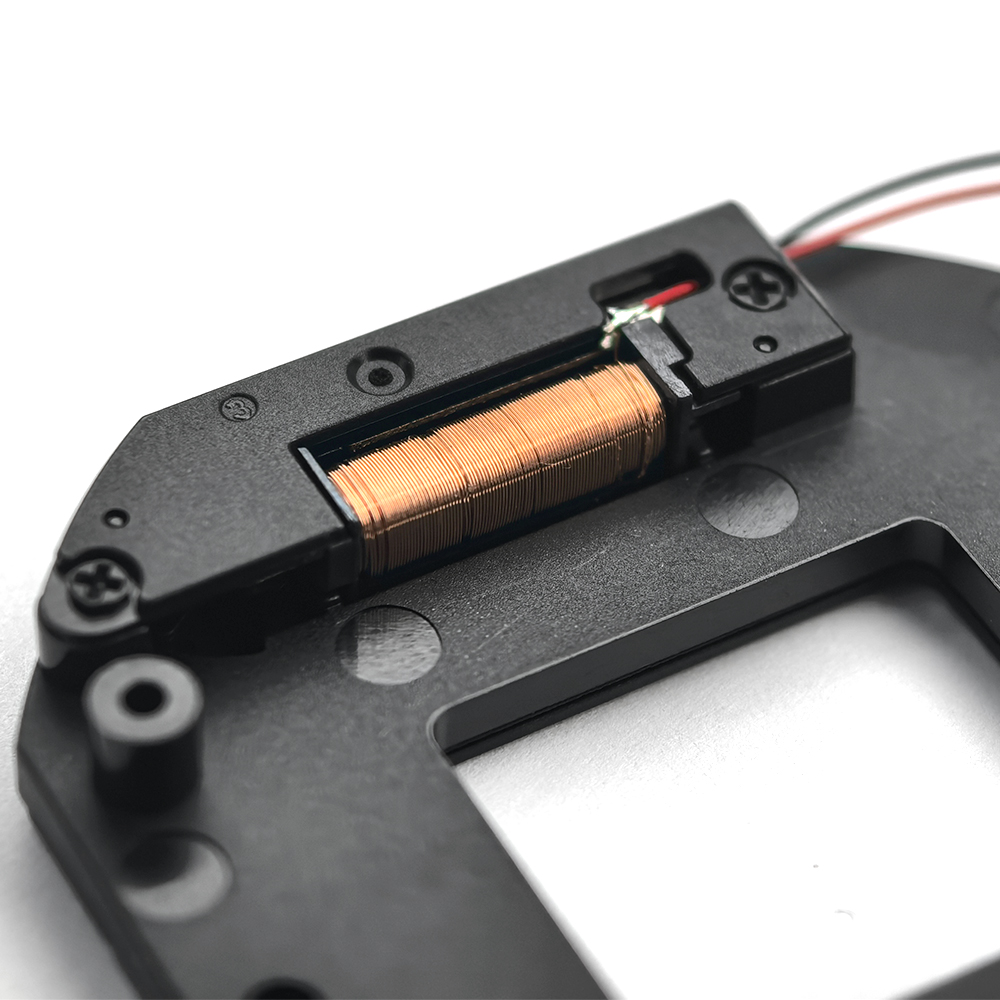

- Shutter Cores:

These incorporate a mechanical shutter that periodically blocks the detector’s view to perform calibration. This process eliminates temperature drift and ensures stable, accurate imaging. - Shutter-less Cores:

Compact and designed for continuous video output, these rely on software algorithms for compensation, trading some accuracy for seamless operation.

The Link to Optical Shutters

The concept of the shutter in thermal imaging connects naturally with the broader optical shutter technology used in visible-light and laser-based systems. While the purposes differ—exposure control in visible systems versus calibration in infrared—the shared principle is clear: precise light control is the foundation of reliable imaging.

Optical shutters are engineered to manage exposure time, light intensity, and synchronization with high accuracy. When applied to thermal imaging systems, these mechanisms enhance calibration performance, improve durability, and extend adaptability across environments.

Applications

- Drones (UAVs):

Capturing accurate heat signatures during flight - Night Vision Devices:

Reliable calibration in low-light or no-light conditions - Industrial Inspection:

Ensuring precise detection of temperature variations in components - Security Cameras:

Delivering consistent and accurate monitoring around the clock

Whether in visible-light or infrared systems, optical shutters are indispensable components that guarantee accuracy, stability, and reliability. By integrating optical shutter principles into thermal imaging cores, industries can achieve next-generation performance, ensuring sharper, more dependable results across critical applications.