lnfrared thermal imagers have become indispensable tools in the automotive industry, allowing engineers and technicians to detect overheating, friction, and electrical failures in car components. By visualizing temperature distribution, these devices help ensure safety, improve efficiency, and prevent costly breakdowns. To achieve such precise detection, infrared thermal imagers often integrate an additional mechanism: the thermal shutter, which plays a crucial role in maintaining accuracy, stability, and detector protection.

Automotive Applications of Infrared Thermal Imagers

Infrared thermal imagers can quickly identify temperature anomalies in different parts of a car. For example, they are widely used in detecting engine overheating, brake system wear, tire performance, electrical system faults, air conditioning efficiency, and even interior safety. To maintain accuracy and reliability in these applications, optical shutters are integrated to periodically calibrate the detector and provide consistent reference frames. These applications allow early identification of potential risks, ensuring safer and more reliable vehicles.

The Hidden Role of Optical Shutters

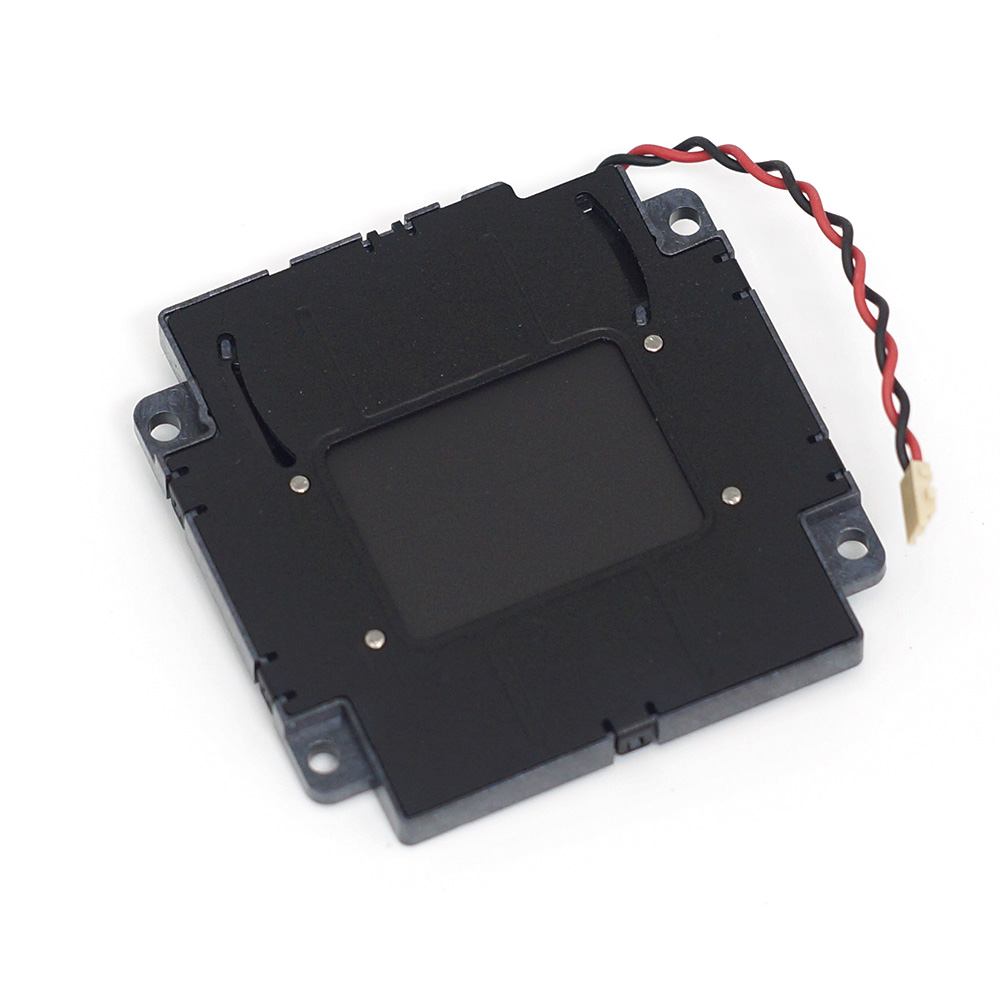

To achieve accurate and stable imaging in these automotive applications, the optical shutter is a critical internal component. It supports calibration, detector protection, and environmental adaptability.

- Calibration and Non-Uniformity Correction

The optical shutter periodically blocks the detector to provide a uniform reference frame, reducing fixed-pattern noise. This ensures that thermal images of engines, batteries, and other components remain precise and trustworthy.

- Protection Against Strong Radiation

When thermal imagers measure high-temperature components like brake discs or exhaust systems, the optical shutter protects sensitive detectors from prolonged exposure, extending their service life.

- Environmental Adaptability

Automotive inspections are carried out in various environments, from factory workshops to outdoor service stations. Optical shutters help maintain consistency by recalibrating under changing conditions, ensuring reliable measurements in diverse settings.

Application Examples

- Engines: Identify overheating and uneven heat distribution; shutters ensure accurate calibration and consistent readings.

- Brakes: Monitor wear and high temperature; shutters protect detectors from overload and thermal stress.

- Batteries and Electrical Systems: Detect abnormal heating; shutters reduce thermal drift for long-term stability.

- Exhaust Systems: Ensure consistent performance monitoring under strong thermal radiation.

Infrared thermal imagers are revolutionizing automotive diagnostics, but their effectiveness depends not only on advanced infrared technology but also on the integration of optical shutters. By offering calibration, stability, detector protection, and environmental adaptability, optical shutters enhance the accuracy and reliability of automotive inspections.

If you would like to learn more about optical shutters and their applications in infrared thermal imaging, feel free to contact us!