Infrared thermal imaging technology is a technique that converts invisible infrared radiation into visible thermal images. This technology has become a core tool in multiple industries, from security monitoring to industrial inspection, drones, and night vision systems. One of the key components that determines image quality and accuracy in this system is the infrared shutter.

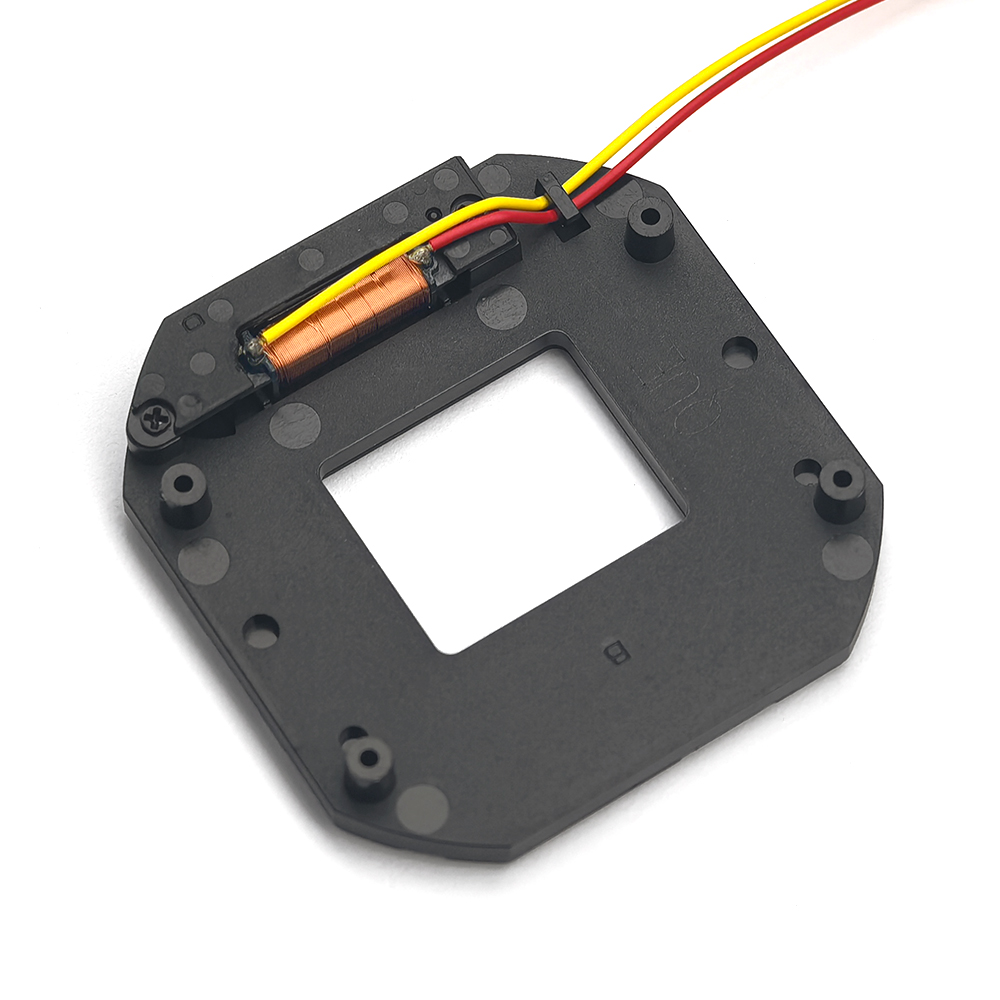

1In thermal imaging technology, infrared shutter relies on mechanical shutter periodic occlusion detector calibration to effectively eliminate temperature drift, ensure imaging stability and temperature measurement accuracy.

1Application Fields

1Drones: Capturing precise thermal signals during flight

1Night vision equipment: achieve reliable calibration under low light or no light conditions

1Industrial testing: Accurately identify temperature differences in components

1Security camera: provides stable and accurate monitoring images

1Relationship between infrared shutter and Other optical shutter

1The shutter in a thermal imaging system, also known as a Blade shutter, is calibrated. Plays a crucial role in thermal imaging systems; There is a natural connection between infrared shutter and optical shutter technology in visible light or laser applications. Although the two have different application goals – the former is mainly used for calibration, while the latter is mostly used for exposure control – their core principles are the same: precise light control is the foundation of reliable imaging.

1Whether in visible light systems or infrared imaging systems, optical shutters are key components that ensure accuracy, stability, and reliability. When its principle is applied to the core of infrared thermal imaging, it can drive imaging technology towards a new generation of high-performance solutions, bringing clearer and more reliable results to various industries.

1